3D printing vs Injection Moulding

Share

What's better? 3D printing or Injection Moulding?

The answer of course really depends on the use case, here's why:

While injection moulding remains a viable option for large-scale production runs, 3D printing offers distinct advantages for one-off prints and small batch productions. Its cost-effectiveness, speed, flexibility, ability to handle complex designs, and material efficiency make it an attractive alternative for manufacturers looking to innovate and streamline their production processes. As technology continues to advance, the capabilities of 3D printing are only expected to grow, further solidifying its place in the manufacturing industry.

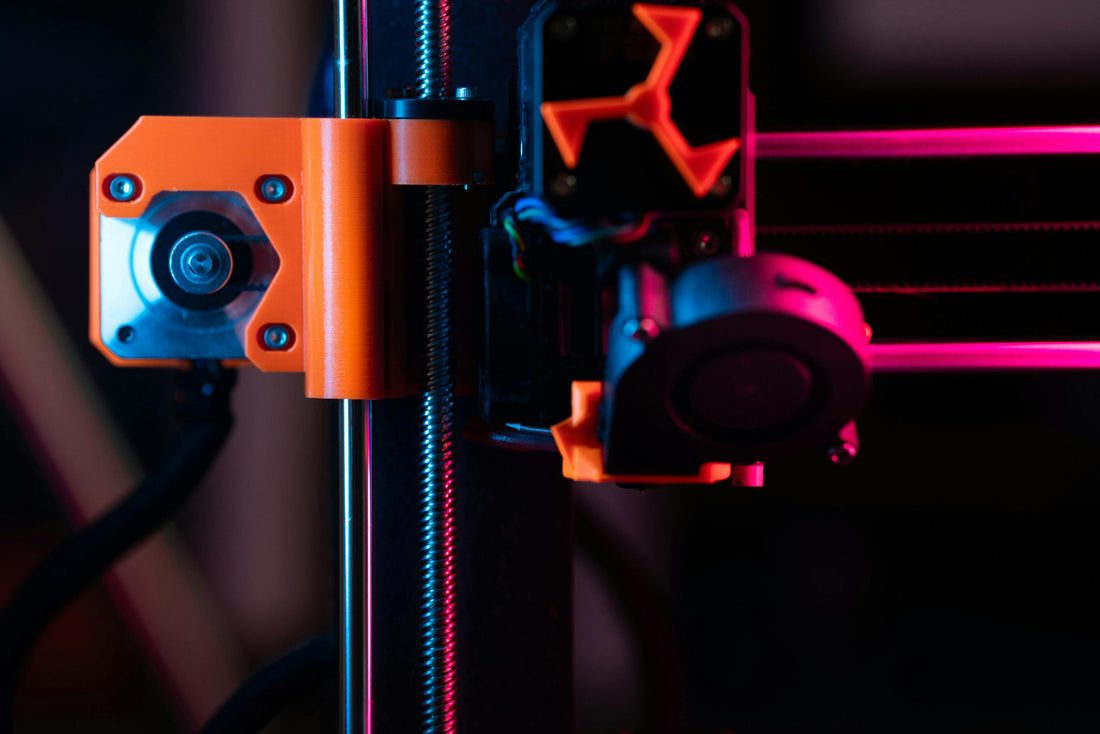

3D printing has revolutionized the manufacturing landscape, offering unique advantages over traditional methods like injection moulding, particularly for one-off prints and small batch productions. Here’s a closer look at why 3D printing stands out in these scenarios:

Cost-Effectiveness

One of the most significant benefits of 3D printing is its cost-effectiveness for small production runs. Injection moulding requires the creation of a mold, which can be prohibitively expensive for small quantities. The initial setup costs for injection moulding include designing and manufacturing the mold, which can run into thousands of dollars. In contrast, 3D printing eliminates the need for molds, drastically reducing startup costs. This makes it an ideal solution for prototyping and small batch production, where the cost per unit can be significantly lower.

Speed and Flexibility

3D printing excels in terms of speed and flexibility. The process of creating a mold for injection moulding can take weeks or even months. Once the mold is ready, any changes to the design require a new mold, which is both time-consuming and expensive. On the other hand, 3D printing allows for rapid prototyping and quick iterations. Designs can be modified digitally and printed within hours, enabling faster turnaround times and greater flexibility in the development process. This agility is particularly beneficial for industries where time-to-market is critical.

Design Complexity and Customization

Another area where 3D printing shines is in its ability to handle complex designs and customization. Injection moulding is limited by the constraints of the mold, making it difficult and costly to produce intricate geometries or customized parts. 3D printing, however, can easily create complex shapes and structures that would be impossible or impractical with traditional methods. This capability opens up new possibilities for innovation and customization, allowing manufacturers to produce highly specialized parts tailored to specific needs.

Material Efficiency

3D printing is also more material-efficient compared to injection moulding. Injection moulding often results in significant material waste, as excess plastic is discarded during the molding process. In contrast, 3D printing is an additive process, meaning that material is added layer by layer to build the final product. This results in minimal waste, making 3D printing a more sustainable option. Additionally, the ability to use a wide range of materials, including biodegradable and recycled plastics, further enhances its environmental benefits.